Introduction

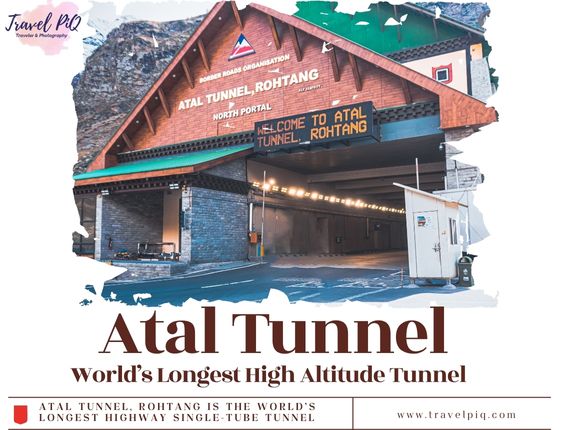

Hello or Namaste, all you travelers out there! I am the adventurer behind Travel Piq, a traveler and storyteller living in the vibrant land of India. Today, we will tell you about an amazing marvel of engineering of tunnel. Atal Tunnel Rohtang is the world’s longest highway single-tube tunnel and it is 10,075 ft. above sea level.

Manali city located in Himachal Pradesh, India, where Atal Tunnel is built. This tunnel connects Manali to Lahaul and Spiti valleys. These routes used to be closed during the winter season due to heavy snowfall, but traffic is possible throughout the year through Atal Tunnel. Earlier, these areas were not possible to reach when the Rohtang Pass was closed.

Atal Tunnel, Rohtang is the world’s longest highway single-tube tunnel

Historical Context

The Atal Tunnel was started on 3 June 2000, although it is not that the idea had not come before. But the then Prime Minister Atal Bihari Vajpayee announced the project. With the construction of this tunnel, the route from Manali to Lahaul Spiti would have been possible for traffic throughout the year or it was important for the Indian Army.

Timeline of construction

| Date/Year | Work | Description |

| 3 June 2000 | Project announced | The Prime Minister Atal Bihari Vajpayee announced the project. |

| 6 May 2002 | Assignment of responsibility | Border Roads Organisation (BRO) was assigned the responsibility of the project. |

| 28 June 2010 | Foundation Stone | Sonia Gandhi laid the foundation stone of the project. |

| June 2012 | Tunnel excavation | 3.5 km of tunnel excavation completed. |

| October 2013 | Excavation halt | Work halted due to collapse of a portion. |

| 13 October 2017 | Both ends joined | Both ends of the tunnel joined; Defence Minister Nirmala Sitharaman visited. |

| September 2018 | Emergency use | The tunnel was used for evacuation due to bad weather in Lahaul. |

| 17 November 2019 | Bus service trial | Bus service trial through tunnel begins for residents of Lahaul and Spiti valleys. |

| 25 December 2019 | Renaming | The tunnel was officially renamed from Rohtang Tunnel to Atal Tunnel. |

| 3 October 2020 | Inauguration | Prime Minister Narendra Modi inaugurated the Atal Tunnel. |

Companies involved in construction

The following major companies collaborated with the Border Roads Organisation (BRO) in the construction of Atal Tunnel, Rohtang:

- AFCONS Infrastructure Limited: The lead construction company that assisted BRO in building the tunnel.

- Strabag AG: Austrian company that provided technical and engineering support.

- Larsen & Toubro (L&T): Indian multinational company that was involved in various construction phases of the tunnel.

Atal Tunnel, Rohtang is an example of Indian engineering and technical prowess. It has reduced the distances of many areas of Himachal Pradesh and provided them with traffic facilities throughout the year. We will understand in detail the many challenges faced in this tunnel. Despite all the difficulties, engineers successfully completed the project, and today it stands as a symbol of pride for the country.

Engineering Marvel

Technical Specifications

- Length: 9.02 km

- Altitude: Located at an altitude of 3,000 meters above sea level

- Width: 10.5 meters

- Two-lane tunnel: Width of each lane 3.6 meters

- Footpaths: 1 meter wide footpaths on each side

- Ventilation system: State-of-the-art ventilation system, supplying fresh air every 500 meters

- Fire safety: Fire safety system every 60 meters

- Emergency exit route: Emergency exit route every 150 meters

- CCTV surveillance: Continuous monitoring with CCTV cameras every 250 meters.

- Radio communication system: Radio communication system inside the tunnel

- Power supply: Diesel generator set to ensure power supply

- Drainage system: High capacity drainage system to drain out water

Engineering Challenges

The construction of the Atal Tunnel was not easy; it was full of geographical and technical challenges. Let us understand some engineering challenges in detail during the construction:

Geological challenges

- The tunnel was constructed between the complex geological structures of the Eastern Pir Panjal Range of the Himalayas, where the danger of landslides and rock falls always remains.

- Engineers estimated that the water level could rise due to the Seri Nala fault zone in the middle of the tunnel, potentially hindering the work in a few kilometers.

Climatic difficulties

- The tunnel was constructed at an altitude of 3,000 meters above sea level, where temperatures can fall to -20 degrees Celsius.

- Heavy snowfall and cold weather forced construction crews to stop work several times, thereby increasing the overall construction time.

Technical challenges

- State-of-the-art technologies and machines like New Austrian Tunneling Method (NATM) had to be used. NATM was used to construct this tunnel as there were water challenges in the Seri Nala fault zone ahead.

- It was a challenge to streamline the ventilation and drainage system of the tunnel to ensure fresh air and proper drainage of water inside the tunnel.

Safety Challenges

- Ensuring the safety of workers was a major challenge, especially when excavation and construction work was going on inside the tunnel.

- They installed fire protection systems every 60 meters and emergency exit routes every 150 meters to prevent fire.

Logistic Challenges

- Transporting material and machinery to the tunnel construction site was a difficult task, especially in remote and inaccessible areas.

- Availability and management of necessary resources at the construction site was also a major challenge.

Environmental Challenges

- It was important to maintain environmental balance during tunnel construction to ensure that the local ecology was not harmed.

- It was also necessary to properly manage the waste and debris generated during the construction work.

Innovations and Technologies

Engineers constructed the Atal Tunnel using several cutting-edge innovations and technologies. Let us understand some of the technical methods given below:

New Austrian Tunneling Method (NATM)

- The engineers used the New Austrian Tunneling Method to dig the Atal Tunnel, shaping the rock or soil formations around the tunnel into a horseshoe section.

Ventilation System

- They have installed a state-of-the-art ventilation system to ensure the supply of fresh air inside the tunnel. Additionally, They installed ventilation systems every 500 meters, maintaining the air quality inside the tunnel.

Fire Safety System

- They have used a fire safety system every 60 meters inside the tunnel, which includes fire hydrants, ensuring enhanced safety measures. This system controls the fire in an emergency and gives priority to the safety of all the passengers.

Emergency exit routes

- They have built emergency exit routes every 150 meters in the tunnel, providing safe exit routes in case of emergency. Additionally, engineers constructed another tunnel below, intended to evacuate everyone in case of emergency.

CCTV surveillance

- They have installed CCTV cameras every 250 meters inside the tunnel, thereby ensuring continuous monitoring and security. This system is helpful in detecting any unusual activity and taking action.

Radio communication system

- They installed a radio communication system inside the tunnel to ensure uninterrupted communication and enable quick contact in any emergency situation. Apart from this, there is a facility of loudspeaker for any announcement.

Drainage system

- A high capacity drainage system has been built for drainage of water. This system prevents water accumulation inside the tunnel and keeps the structure safe.

Construction Process

The construction of the Atal Tunnel was a complex and detailed process, which faced many technical and geological challenges. Let us understand the process of tunnel construction.

Planning and Survey

- Geological Survey: Initially, the geological conditions of the Eastern Pir Panjal range of the Himalayas were surveyed. This included the study of rock structure, water level and other geological factors.

- Detailed Project Report (DPR): Based on the geological survey, engineers prepared a detailed project report describing the length, height, construction technique, and possible challenges of the tunnel.

Tunnel Design and Planning

- Tunnel Design: The design phase planned the tunnel width, height, ventilation, drainage, and emergency exit routes.

- Cutting Edge Technology: They chose the New Austrian Tunneling Method (NATM) to ensure faster and safer construction.

Excavation and Support

- Pilot Tunnel: Before excavating the main tunnel, they constructed a pilot tunnel to understand the geological conditions and guide the excavation of the main tunnel.

- Support System: During excavation, they used steel ribs, rock bolts, etc., to stabilize the tunnel roof and walls.

Excavation of Main Tunnel

- New Austrian Tunneling Method (NATM): The excavation of the main tunnel was done using NATM. This technique was used to excavate and support the tunnel, which provides excavation and support by using the natural strength of the structure.

Ventilation and Drainage System

- Ventilation System: They have installed a ventilation system to ensure a supply of fresh air inside the tunnel. Additionally, they have installed ventilation shafts every 500 meters.

- Drainage System: They have built a high-capacity drainage system to drain out water. Consequently, this prevents water accumulation inside the tunnel and keeps the structure safe.

Fire Safety and Emergency Features

- Fire Safety System: They have installed a fire safety system every 60 meters inside the tunnel. Consequently, this ensures a quick response in case of an emergency.

- Emergency Exit Routes: They have built emergency exit routes every 150 meters. As a result, these provide a safe exit from the tunnel in case of an emergency.

CCTV and Communication System

- CCTV Surveillance: They have installed CCTV cameras every 250 meters inside the tunnel. Consequently, this ensures continuous surveillance and safety.

- Radio Communication System: They have installed a radio communication system inside the tunnel to ensure uninterrupted communication and quick contact in case of any emergency. Consequently, communication remains seamless and responsive.

Interior Work and Finishing Touches

- Internal Structure: They constructed the concrete lining, roadway, and pavement to make the internal structure of the tunnel strong and safe.

- Finishing Touches: They installed lighting, signage, and other facilities inside the tunnel to ensure smooth and safe traffic movement.

Journey to Atal Tunnel

How to Reach

By Air

Nearest airport to Atal Tunnel is Bhuntar Airport located in Kullu Manali. This airport has connectivity to major cities, from the airport; you can take a bus or taxi to reach Atal Tunnel.

By Road

The distance from Manali (NH-3) is 25 km to the South Portal side of Atal Tunnel where you can drive and go by road.

By Railways

There are not many rail options to reach Atal Tunnel as the nearest railway station is Joginder Nagar which is at a distance of 150 km. It would be better to take a train to Chandigarh and then take a bus or taxi to reach the tunnel via Manali.

Best Time to Visit

Summer Season

Summer is the best time to visit Atal Tunnel Rohtang as the weather is pleasant and both sides of the tunnel are beautiful.

Winter Season

Winters can make it difficult to reach Atal Tunnel Rohtang due to heavy snowfall, but it can be a unique experience to enjoy the view here.

Monsoon Season

It is more risky to visit Atal Tunnel Rohtang during rainy months as the roads can be slippery during this time of rain and there can also be a risk of landslides.

Tunnel Experience

Inside the Tunnel

- Modern design: The design of the tunnel is state-of-the-art, which includes better ventilation and lighting systems. The lighting and cleanliness inside the tunnel is excellent.

- Fresh air: The ventilation system provides a fresh air inside the tunnel, making the journey smooth and comfortable.

- Safety signs: There are safety signs and guidelines installed at various places inside the tunnel to guide the travelers.

Safety Features

- Ventilation system

- Fire protection system

- Emergency exit route

- CCTV surveillance

- Radio communication system

- Drainage system

Practical Information for Travelers

Travel Tips

- Follow all signs and directions inside the tunnel. Observe speed limits and avoid overtaking.

- Follow designated routes in case of emergency.

- Avoid carrying any kind of petrol/diesel fuel.

Tunnel Rules

- Do not use horns in the tunnel. This causes noise pollution and may inconvenience other commuters.

- Avoid stopping inside the tunnel. In case of an emergency, stop at designated places only.

Personal Stories

I felt very happy and proud after visiting the Atal Tunnel Rohtang. I was proud to know that India has built the world’s longest high-altitude tunnel. It is not only a symbol of technical excellence but also a symbol of the country’s progress and empowerment.

This tunnel has not only made the journey of passengers easier but has also established the engineering capability of our country in the world.

Cheers to New Adventures: Join Us at Travel Piq

Hello all adventurous travelers!

Thank you all for joining me on this wonderful journey of engineering & adventure through the blog of Atal Tunnel Rohtang – World’s Longest High Altitude Tunnel.

At Travel Piq, we are all about sharing our passion for travel, photography and exploring new places. Whether you are planning your next vacation or just love absorbing travel inspiration, you will find plenty to satisfy your travel cravings here.

Connect with us

Don’t forget to connect with us on social media! It’s the best way to stay updated on our latest adventures, photography tips.

Discover new additions to our vibrant stock image collection. Capture the essence of your travels with high-quality images. These images bring destinations to life and are available for purchase right here on our website.

Plus, you’ll be part of a vibrant community of fellow travel enthusiasts who share your excitement for exploring the world.

Until next time, keep snapping those pictures, keep exploring new horizons, and keep making memories that last a lifetime.

Safe travels, and see you soon on Travel Piq!

[…] the way back, we had lunch at a mountainside dhaba and saw beautiful waterfalls. The Atal Tunnel was another incredible experience—it reduces travel distance by 45 km, making winter travel much […]

[…] back to Manali via Atal Tunnel after lunch, start your return journey to Manali via Atal Tunnel, which is the longest highway […]